This week, the secondary clarifier and oxidation ditch were successfully reinforced with rebar and poured, with concrete slabs and wall sections continuing to be poured daily. Additionally, all excavations for essential buildings have been completed. Our office remains open during regular hours — Monday through Friday from 9:00 AM to 3:00 PM.

Shoring Installed Along the Aeration Basin

Shoring around the basin will ensure safe excavation of the secondary clarifier.

New Clarifier Pipes Installed, Formed, and Poured

The inlet and outlet pipes for the secondary clarifier have been installed, formed, and poured, making them ready for rebar and the main slab. These pipes will transport treated water and recycle settled microorganisms, which will be reintroduced into the process to continue treating new influent in the oxidation ditch.

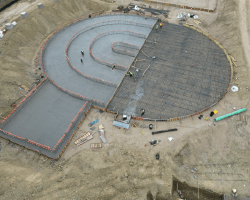

Oxidation Ditch Half Slab Poured, Other Side Rebar Installed

The oxidation ditch now has all rebar placed, with half of the slab poured. This was one of the largest pours to date, comprising approximately 268 cubic yards of cement—equivalent to 542 tons or 1,085,400 pounds.

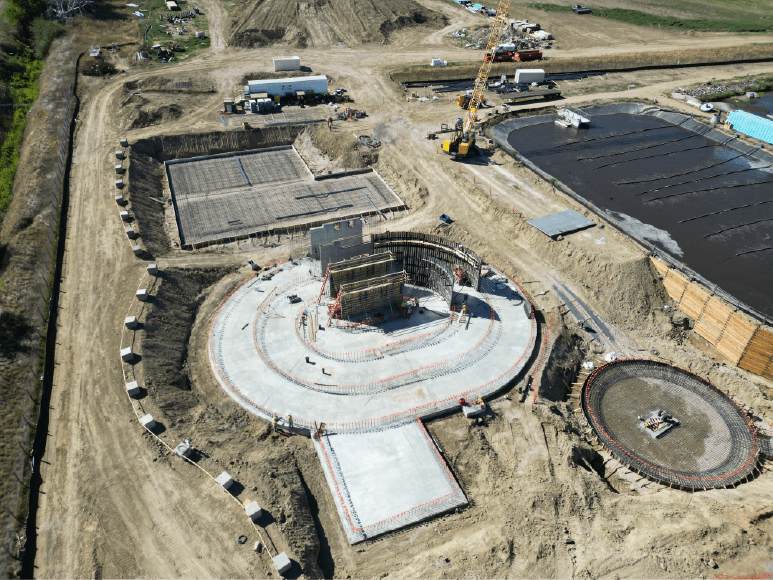

Structural Excavation at Digester and Dewatering Area

This excavation area has been leveled and compacted to minimize settling. The future structure will serve as an onsite dewatering facility that produces what the wastewater industry refers to as “cake.” By using old sludge from the digester and a polymer, we can transform runny sludge into a cake-like substance, making disposal easier.

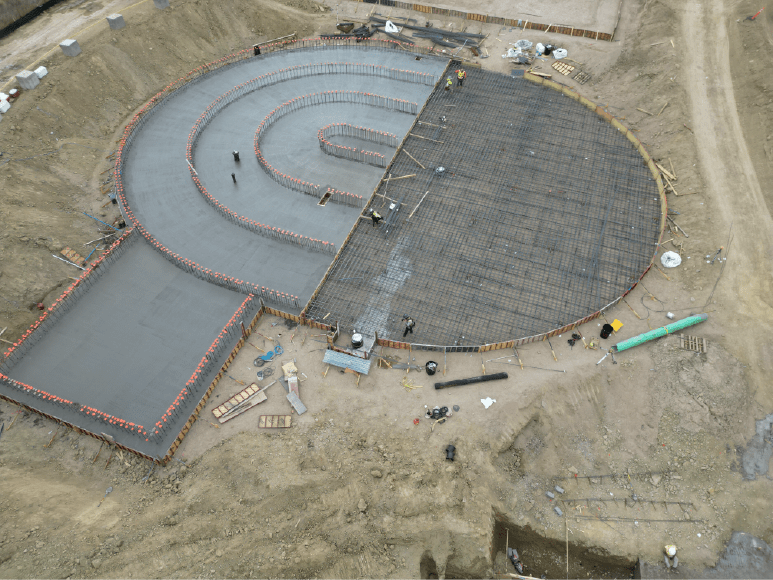

Oxidation Ditch Slab Poured, Wall Sections Formed and Poured

The walls in the oxidation ditch form rings for treatment, with each ring designed for nitrification, denitrification, and phosphorus removal to meet EPA requirements. The innermost ring will serve as the final treatment area before water is sent to the clarifier for settling.

Rebar for the Secondary Clarifier’s Slab Completed

The rebar for the secondary clarifier’s slab is now finished and ready for the cement pour. A layer of grout will be added to account for the slope in the slab, further facilitating microorganism collection.

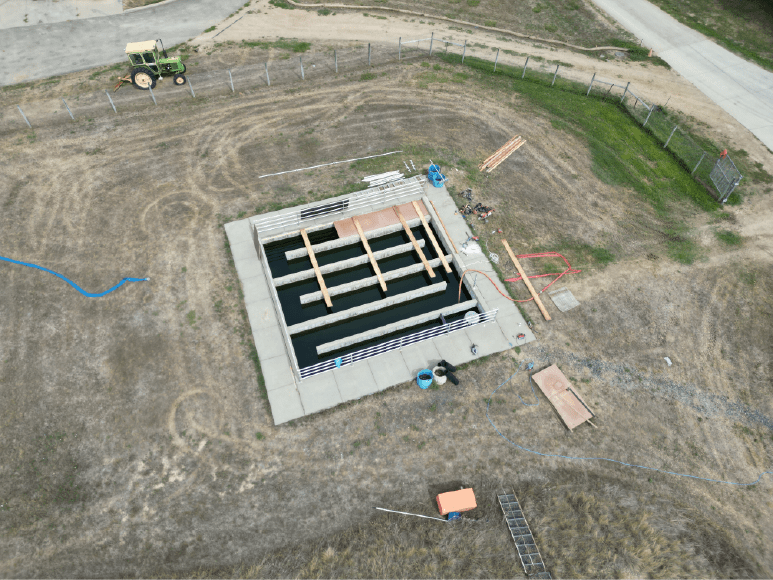

Chlorine Contact Chamber for UV Building Covered

The chlorine contact chamber is now covered with the exception of an access hatch, allowing for sampling and inspection to ensure quality treatment. This covering enables Rice Lake West to begin construction of the UV building and allows Niwot Sanitation to continue treating our effluent before it discharges into Dry Creek.

The first photo shows a partial covering of the chlorine contact chamber, while the second photo displays a complete covering.

What's next?

Our fourth construction update will feature the backfilling of the headworks building, and installation of influent pipes and manholes. The secondary clarifier will have its slab poured, and wall forms/rebar installed. The dewatering building will have rebar completed and a slab poured, along with additional wall sections in the oxidation ditch.